ABOUT EDITORIAL ARTICLES RECIPES PROJECTS NEWS & VIEWS BAKERY LEADERS FORMS

WHEAT – THE BASIC RAW MATERIAL FOR BAKERY INDUSTRY

Shruti Sethi

Senior Scientist

Division of Food Science and Postharvest Technology

Indian Agricultural Research Institute, New Delhi

Wheat is the staple food of the Indian population and is one of the main source of calories and protein. It contributes around 32 percent of total food grain basket of the country. India became the second largest producer of wheat in the world with a production of 95.91 MT and a share of 13.1 percent in global wheat production during 2013-14 (http://agricoop.nic.in). Three species of wheat are cultivated in the country, namely, T. aestivum (95%), T. durum (4%) and T. dicoccum (1%). Cultivation in India has traditionally been dominated by the northern states of India, mainly in Uttar Pradesh, Punjab and Haryana. Other major wheat growing states include Madhya Pradesh, Rajasthan, Bihar and Gujarat. India also exports wheat to many countries, namely, Bangladesh, United Arab Emirates, Indonesia, Turkey and Sudan (APEDA, 2015).

Wheat milling

The major parts of the wheat grain include the seed coat or bran layer, the endosperm and the germ. Bran constitutes about 15% of the grain whereas germ comprises 2.5% and endosperm about 82.5%. Wheat is mainly milled into flour for use in different products. Main aim of milling is to remove both bran and germ and extract the pure starchy endosperm as flour. Prior to the production of flour, wheat is cleaned by separators consisting of agitating screens and forced air currents followed by conditioning i.e. addition of controlled amount of water. This is done for toughening the bran for its subsequent separation from endosperm. Further processes involve breaking, reduction, bleaching and maturation. Breaking and reduction help to reduce the particle size of the grain and production of flour whereas bleaching and maturing are done to yield whiter flour with improved dough handling properties. Blending, which is not common in India, is done to keep grades of flour constant. Different grades of wheat or flour are mixed to get a particular grade of flour. The recovered bran during the milling process is high in nutritive value, and is mostly used for animal feed. The germ is removed from the wheat during milling, because it is high in oil and will adversely affect the keeping quality of flour. All flours obtained by the milling process are not of the same composition percentage-wise. The variation noticeable through analysis when dough is made, are due to the effects of climate, the type of seed, variety, the type of wheats blended and proportions of the wheat used during blending. The storage period of wheat also affects the quality of flour.

Quality characteristics of the grain

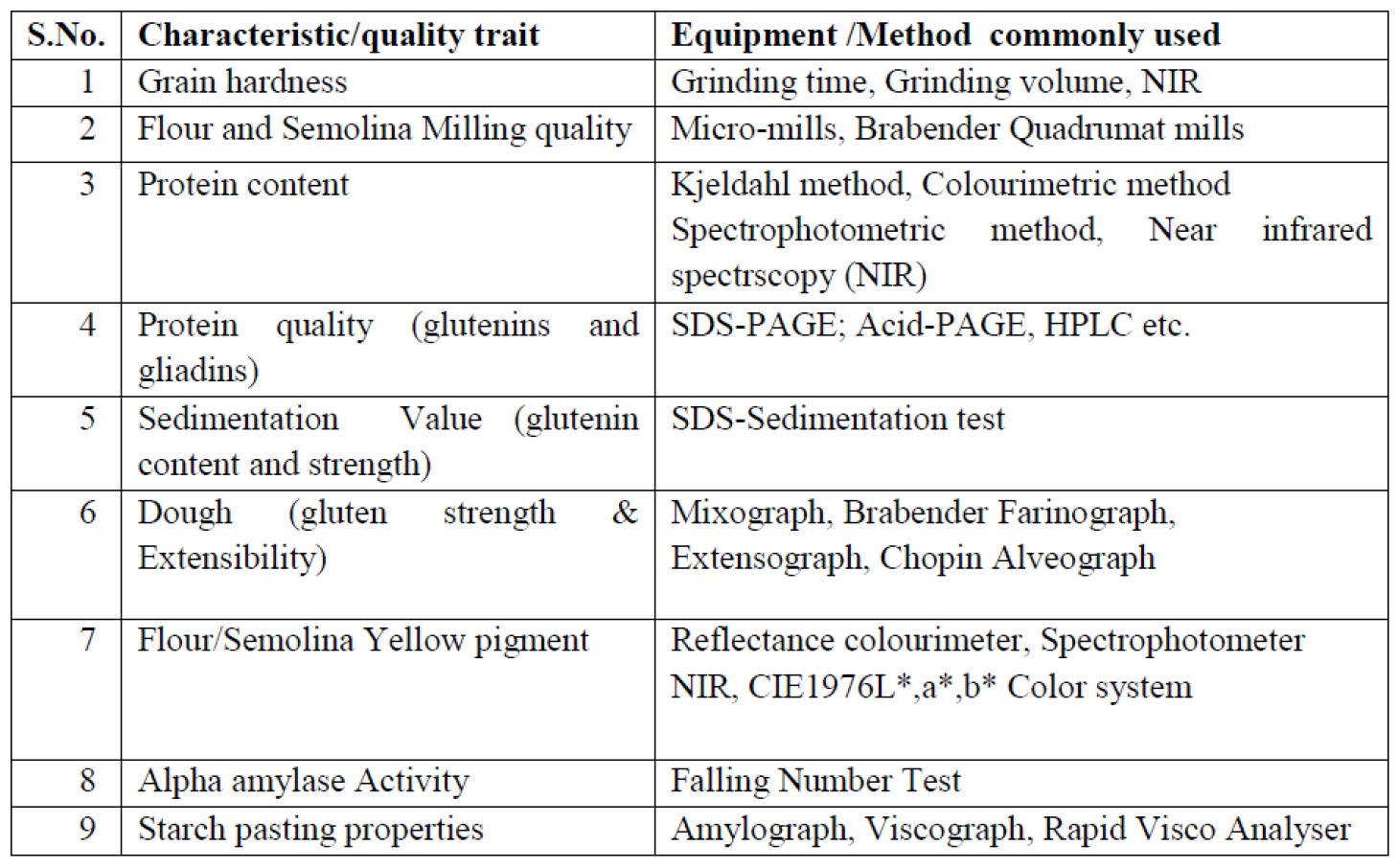

Quality characteristics of wheat can be categorized into physical characteristics and chemical characteristics. Physical quality parameters include test weight i.e., weight per unit volume (kg/hect), vitreousness, colour and hardness of the grain. Chemical quality characteristics, on the other hand, mainly include moisture, protein, starch, ash and fibre. The physical and chemical differences of the wheat grains are the basis for the differences in their quality or suitability for end-use. The common tests used for determination of wheat grain quality are enlisted in Table 1

Table 1: Common Tests used for Determination of Grain Quality

Classification of wheat

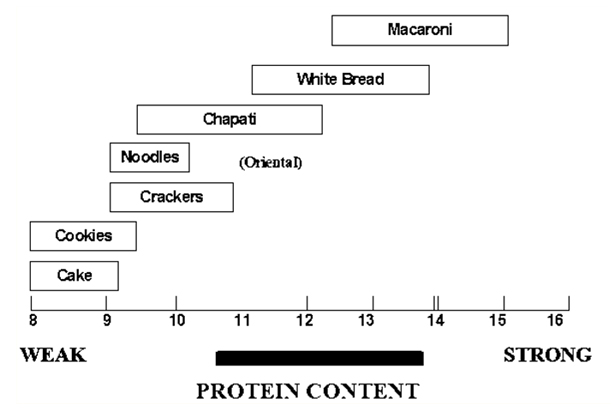

Wheat is classified into distinct categories on basis of grain hardness (soft, medium-hard and hard), colour (red, white and amber) and growing habit (spring or winter) and therefore, varies widely in properties depending on the variety and area where grown. The varieties may be loosely grouped into two general groups, namely hard and soft. The hard wheat is the most desirable for bread production. It mills well and yields good quantities of flour that is high in good quality protein from which strong, elastic doughs can be made with proper development. These doughs have good tolerance to baking conditions with respect to mixing, fermentation, temperature, etc., and have excellent gas holding properties that yields bread with good volume, grain and texture under a wide range of conditions. The hard wheat doughs have high water-absorptive capacities and generally have excellent dough-handling properties when properly matured. The soft wheat, on the other hand, is used principally in the production of flour for cakes, pastries, cookies etc. It is characterized as being low in protein and yields flours which have low water absorption capacity and poor tolerance to mixing and fermentation in bakeshop practice. They handle poorly in bread baking equipment. Thus the soft wheat is considered undesirable for commercial bread production, but is highly desirable for the production of cakes, pastries and cookies. Protein content of the wheat thus governs its end use. The following figure gives the relationship between protein content and its use in manufacture of different wheat products.

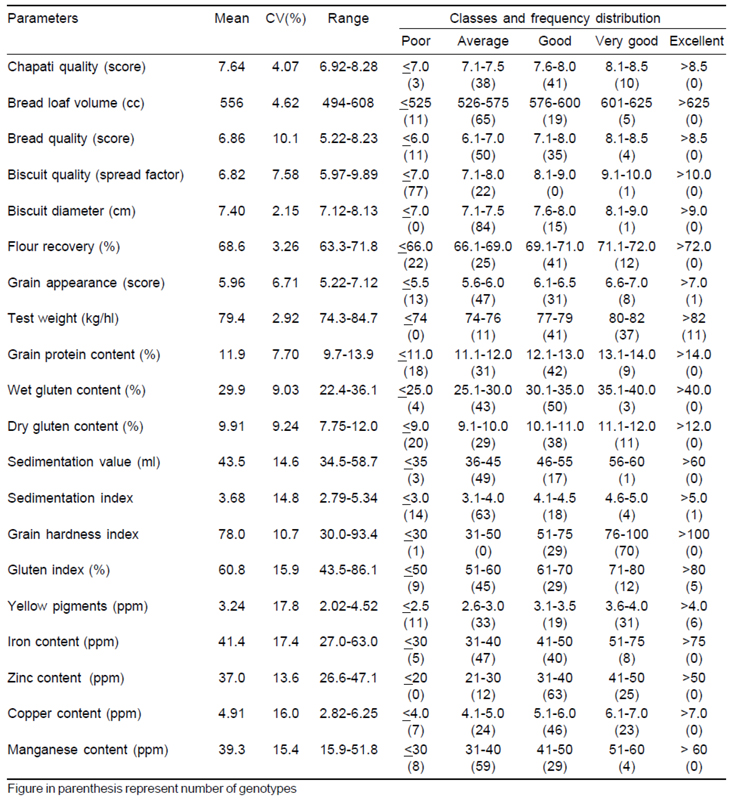

The quality of wheat maybe governed by several factors including climate, variety of wheat and the soil. In our country, the All India Coordinated Wheat and Barley Research Improvement Project (AICW&BIP) examines all pipeline varieties for traits related with marketability (grain appearance), industry (hardness index, sedimentation value, grain protein content gluten index, test weight, flour recovery), micronutrients (yellow pigments, iron, zinc, copper and manganese) and end-usage (chapati, bread, biscuit). Mohan et al (2013) have characterized 100 popular Indian bread wheat cultivars for grain quality as shown in Table 2.

Table 2: Mean performance, diversity and frequency distribution in grain quality of 100 Indian wheat varieties

Flour

The production of uniform bakery products requires control over the raw materials used in their formation. Since flour is the basic raw material used in all baked products, its quality assessment is of prime importance which ultimately affects the end product quality. Flour developed from wheat from different cultivars and locations can vary considerably in its protein quality, protein quantity, ash, moisture, enzymatic activity, color, and physical properties. It is essential to monitor the variations in these characteristics of the flour so as to get consistency in the end products.

Flour mainly consists of starch, protein and ash. During milling some of the starch is broken down which acts as food for the disatatic enzymes and the yeasts. The action of yeast leads to production of carbon dioxide and expansion in the loaf volume. Proteins of the flour comprise the soluble and insoluble fractions. The soluble proteins in the flour provide nourishment to the yeasts to carry out fermentation. The insoluble protein comprises the gliadin and glutenin fractions which when mixed with water form the gluten that is responsible for formation of structure of baked products. Generally hard wheat is high in protein whereas soft wheat is low in protein. The variation in ash and protein within a class may be as great as variation between classes. Ash content of flour is considered as a measure of the degree of separation of the flour from a particular wheat blend but is not a reliable index of baking quality. The value of wheat over other cereals lies in its gluten forming properties. Bread flour should contain more than 10.5% protein and not more than 0.4% ash. It should also possess high absorption and good mixing tolerance which enables it to be mixed for longer periods without breakdown of gluten. Cake flours should contain less than 10% protein and 0.4% ash, and should have low water absorption.

Bureau of Indian Standards has laid down certain specifications (IS 7463: 2004) for the wheat flour (maida) used in the bakery industry that it should conform as shown in the Table 3.

Table 3: Requirements for Wheat Flour (Maida) for Use in the Bakery Industry

| S. No. | Requirement of wheat flour (Clause 3.3) | |||

| Characteristic | For Biscuit Industry | For Bread Industry | For Cake Industry | |

| 1. | Moisture, percent by mass Max | 13.0 | 13.0 | 13.0 |

| 2. | Total ash (on dry basis), percent by mass, Max | 0.5 | 0.5 | 0.5 |

| 3. | Acid insoluble ash (on dry basis), percent by mass | 0.05 | 0.05 | 0.05 |

| 4. | Gluten (on dry basis), percent by mass, Min | 7.5 | 9.5 | 7-9 |

| 5. | Total protein (on dry basis), percent by mass, Min | 9.0 | 11.0 | 9.0 |

| 6. | Alcoholic acidity (on dry basis), percent by mass, Max | 0.1 | 0.1 | 0.1 |

| 7. | Water absorption, percent, Min | 55 | 60 | — |

| 8. | Maltose, percent | — | 2-3 | — |

| 9. | Sedimentation value, Min | 22 | 22 | — |

| 10. | Total bacterial count per gram, Max | 100 000 | 100 000 | 100 000 |

| 11. | Aflatoxin, µg/kg, Max | 30 | 30 | 30 |

| 12. | E. coli per gram, Max | Absent | Absent | Absent |

| 13. | Yeast/mould count per gram, Max | 10000 | 10000 | 10000 |

Types of Flour

Different types of flours are available to be used for different types of end products. This is owing to the wide range of different types of wheat that are grown globally. Milling helps to convert the inedible raw wheat grain to flour that is having multiple uses. When water is mixed into the flour, the flour proteins combine to form gluten. It is gluten which forms a network that will stretch as the dough ferments and carbon dioxide gas is released. On baking this stretched gluten network sets to give the structure and texture to baked products. Hence the amount and type of protein present in the flour governs its end use.

Wholemeal flour/ White flour

Wholemeal flour contains all parts of the wheat grain including the outer layers of bran and the germ. Therefore, it is rich in fat, fibre and proteins. White flour contains only the inner portion of the grain called the endosperm. Wholemeal flour requires comparatively more water to make dough of desired consistency because the bran absorbs more water than the white portion of the grain.

Patent flour

The purest flour, devoid of bran specks, selected from the purest flour streams released in the mill, is often called patent flour. It has very low ash content.

Bread flour

Bread making flour has a medium to high protein content. It is referred to as strong flour and is used for products leavened with yeast. Strong or high protein flour is needed to ensure that sufficient gluten is formed to produce bread of good volume and appearance.

All-purpose flour

It is made from a blend of hard wheat and soft wheat flours. As the name suggests, it is intended for most baking needs and can be used for cookies, cakes, crackers and similarly baked products. It has a slightly higher protein content (10-11%) and less starch.

Self raising flours

This is a type of all-purpose flour that has salt and a leavening agent added to it. The aerating agents cause batters to rise when heated. The flour and raising agents are sifted together many times to ensure even distribution and consistent product quality. Self raising flour can be substituted for all-purpose flour in a recipe by reducing salt and baking powder accordingly. It is commonly used in biscuits and cookies, but is not recommended for yeast breads.

Pastry Flour

This type of flour has properties that fall between all-purpose flour and cake flour. It is usually made from soft wheat for pastry making, but can be used for cookies, cakes, crackers and similarly baked products. It has a slightly higher protein content than cake flour and less starch.

Cake Flour

This is a fine-textured flour milled from soft wheat and has a low protein content. It is used to make all types of baked goods like cakes, cookies, crackers, quick breads and some types of pastry. Cake flour has a higher percentage of starch and less protein than bread flour, which keeps cakes and pastries tender and delicate. The protein needed to form the structure of cakes and biscuits is not from the flour used but from other ingredients such as egg.

Recommended wheat varieties for different baked products

Indian Institute of Wheat and Barley Research (erstwhile Directorate of Wheat Research), Karnal has categorized different wheat varieties grown in different agro-climatic regions of the country suitable for varied end uses as given in Table 4.

Table 4: Promising wheat varieties for different products

| Product | Promising varieties |

| Chapati(>8.0/10.0) | NWPZ : C306, Raj3765, HD2285, PBW226, PBW175, PBW373NEPZ : C306, K8027, K9107, MACS6145, UP262, NW1014, HUW234, HUW533, HD2888, K0307, HI1563CZ : Lok1, C306, Sujata, HI1500, HW2004, DL-788-2, GW173, GW273, GW322, Raj3077, HI1531, HD2864, MP3336PZ : Lok1, HD2833, GW496, HD2987, NIAW1415 |

| Bread(> 575ml loaf volume) | NHZ : HS240, VL738NWPZ : HD2285, PBW396, WH1021NEPZ : HD277, HD2733, NW2036, DBW14, DL 788-2CZ : Lok1, GW120, GW173, GW190, GW496, HD2864, HD2932, MP1203PZ : HI977, HD2189, HD2501, HD2781, DWR162, DWR195, MACS2496, Lok1, NI5439, NIAW34, NIAW917, Raj4083, HD2932, PBW596, MACS6222, NIAW1415 |

| Biscuit (>8.0 spread factor) | NHZ : Sonalika, HS 490NWPZ : UP2425 |

| Pasta(>6.5/9.0) | NWPZ : PDW233, WH896, PBW34, PDW291, PDW314, WHD943CZ : HI8498, HD4672, Raj1555, A-9-30-1, HI8627, HI8713PZ : MACS2846, DDK1009, NP200, HI8663 |

NWPZ : North Western Plains Zone; NEPZ : North Eastern Plains Zone; CZ : Central Zone; PZ : Peninsular Zone; NHZ : Northern Hills Zone

Source: www.krishisewa.com

References

1. APEDA. 2015. www.apeda.com. (accessed July 2015).

2. Mohan, D., Gupta, R. K. and Verma, A. (2013). Characterization of popular bread wheat cultivars of India for grain quality and the stable genetic resource, Indian J. Genet., 73(1): 14-22.

3. http://agricoop.nic.in. 2014. Pocket Book on Agricultural Statistics Directorate of economics and Statistics, DAE, Ministry of Agriculture, GOI.

4. http://www.krishisewa.com/cms/articles/production-technology/347-wheat-quality-standards.html (accessed July 2015).